The Power Amplifier Build – Prologue, Part 1

The Power Amplifier Build – Prologue, Part 1

Big Tubes, Tank Circuits and Design Philosophy

This project started brewing back in 2019 (actually, even before that), and by 2020 I had begun collecting the last pieces and putting the plan together. I had previously built an amplifier using 813s, but I wanted to take things up a notch — both in terms of scale and concept.

One of the builds that really caught my eye was from EX8A. Although my final design diverges significantly from his, his approach showed a lot of clever problem-solving. In particular, his plate choke switching network intrigued me.

Clarifying EX8A's Choke Design

EX8A uses a conventional DC feed with the plate choke placed directly at the tube anodes. What makes his approach interesting is the use of relays to switch different segments of the plate choke. This, in combination with a bypass capacitor and the tubes' internal capacitance, creates a parallel resonant circuit.

The purpose is twofold:

-

To avoid destructive series resonance, which can damage the choke if it aligns with a harmonic or operating frequency.

-

To reduce the effective tube capacitance on higher bands, where the parallel resonance is used to cancel part of the tube’s internal capacitance.

This technique is particularly helpful when working with high-capacitance tubes — especially in parallel configurations — where performance at higher frequencies would otherwise be compromised.

That said, I’ve decided to skip this approach in my own design.

Why Series Feed Instead?

In my amplifier, the plate voltage is applied on the low-impedance side of the tank circuit — near C2 — rather than directly to the anode via a choke. This has one major advantage: the plate choke sees much lower RF voltage and doesn’t need to work into a high impedance.

There are different ways to do this. You could, for example, if you’re using copper tubing as the tank coil, insert a Teflon-insulated enameled wire inside the coil and loop it past the anode coupling cap — making a coaxial coil, using the center conductor as the DC feed path, feeding at the 50-ohm side while keeping conventional C1/C2 and padding caps in place.

See FIG.2 below from SM6APQ(sk)

Since I wanted an adjustable L1 — a roller coil — that was out of the question.

I decided to elevate the tank circuit to DC anode potential, which means every component tied to the tank has to handle more than 3 kV DC, plus the RF swing on top of that. It adds some complexity in terms of insulation and layout — but I already had a large vacuum variable left over from another project, and some B2B vacuum relays. Perfect for band-switching.

I feed the tank at C2, using a large coupling capacitor to block DC from reaching the antenna connector. I also use the mandatory safety choke at the output; should the blocking cap fail and short, the choke will short the plate supply to ground — either blowing a fuse or triggering the control system to trip the main contactors.

Variable L1 – Precision Without the Hassle

To manage tuning across bands, I use a variable L1 that lets me tweak inductance by around ±3 µH. On higher bands like 10, 12, and 15 meters, L2 is shorted out entirely and L1 alone handles the job.

On lower bands, L1 is in series with L2, which is band-switched using vacuum relays. Because I can fine-tune with L1, I don’t need to move taps on L2. That means I can build L2 as a solid, fixed unit and precisely plan the relay layout — minimizing lead lengths and avoiding trial-and-error with physical coil adjustments.

That makes both the mechanical and RF layout much easier to manage.

A Note on the Tube Itself

The GU-81M might seem like an odd choice in 2025. It’s a pre-WWII design — large internal capacitance, not really suited for higher frequencies, but together with an adjustable L1, I´m confident I´ll get decent output power on 10M as well. Other key points theis tube has, beside the looks, is that it's got a directly heated cathode, meaning there’s no waiting when powering on. Suits my operating style perfectly. Its grids are also very sturdy. During a conversation about protection circuits with a Ukrainian ham, he told me:

“You can spend money on intricate protection systems, but the GU-81 doesn’t care. Its grids will glow white, its plate too, and once the fault is corrected — it’ll work just like before.”

It is clearly visible that the GU-81M shows strong resemblance to tubes from the old Telefunken line of tubes — specifically the RS384. Who could have thought the russians copied things ?

Anyway, ever since I first saw the tube for sale on UR4LL’s site — right next to a schematic by EX8A — I knew I had to build something with it. There’s just something about the visual presence and character of the GU-81 that captured me.

What’s Coming

I’ve got plenty of build photos and notes I’ll dig into over the coming posts. Topics I plan to cover include:

-

Chassis layout and mechanical planning

-

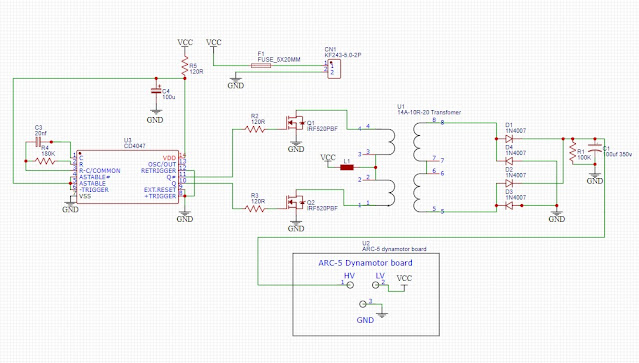

Tube selection and HV power supply design

-

Tank circuit construction and band-switching

-

Arduino-based control logic, safety interlocks and protection circuits

You’ll also find me posting under SA2CLC on some forums — where a few sneak peeks of this project may already be floating around.

Comments

Post a Comment