The power amplifier build part 4, power supplies

Part 4 – Power Supplies

At first glance, power supplies may seem straightforward: transformers, rectifiers, filter capacitors and you’re done. In this project, that’s true for some of the low-voltage rails, but the bias and especially the screen supply needed considerably more thought.

High Voltage Supply

The high-voltage (HV) supply is built around a 3 kVA UI-core transformer, followed by a full-wave rectifier, an oil-filled capacitor, and bleeder resistors.

Since Swedish homes typically have 3-phase service, I wired the two 230 V primaries in series across 400 V. This helps balance the load between phases and reduces light flicker during key-down. The secondary winding has multiple taps; I selected a tap that provides about 3.2 kV DC under load.

|

| The two smaller transformers are 400-230 V transformers. I run them from 230 V, with their secondaries connected in series to get 800 VAC, rectified and smoothed to 1100V. |

Screen Supply

This was the most time-consuming part of the project. Several designs were tried, and quite a few MOSFETs gave their lives before the regulator was stable. I eventually settled on a series-regulated design.

Why not a shunt supply?

A traditional approach is a shunt-regulated screen supply. Here, the voltage is dropped across a series resistor, and an active device (tube, transistor, or MOSFET) shunts excess current to ground to hold the screen at a stable potential. The great advantage is that if the tube ever drives current backwards into the screen supply, the regulator can safely sink it.

The alternative is a series regulator, where a MOSFET (or similar) sits in series with the screen and adjusts its effective resistance to stabilize the voltage. The drawback is that if current flows from the screen back into the supply, a simple series regulator cannot sink it. The screen voltage will rise until something gives.

Negative screen current explained

Normally, the screen grid current flows from the supply into the tube. But under certain conditions – when the plate (anode) voltage falls close to or below the screen voltage – the screen grid can act like the anode. Electrons can be collected by the screen instead of the plate. The result is negative screen current: current flowing from the tube into the supply. If that happens, the screen voltage can soar if the supply cannot sink the negative flowing current.

This behavior is especially associated with:

-

High-gm tetrodes and beam tetrodes (e.g. 4CX/4CX-series, 4-1000A, some TV sweep tubes)

-

Tubes operated with low anode voltage compared to screen voltage

-

Situations with large RF swing at the plate

In those cases, a shunt regulator is the safe option.

The GU-81M, however, is a large, relatively slow tube of 1930s design. Its screen structure and operating parameters make it very unlikely to exhibit negative screen resistance under normal HF amplifier conditions. Besides, all published designs all used series regulation. That convinced me to use a series regulator without the heat dissipation penalty of a shunt design, idling at over 420W dissipation for 400mA capacity.

My implementation

-

Early version: MOSFET series pass element, with a stack of 8×100 V zener diodes for reference. This worked, but temperature drift was severe: voltage crept from 800 V up toward 1 kV as the zeners warmed.

-

Later version: Added closed-loop regulation using an op-amp comparator and feedback divider. This stabilized the output, but the first attempt oscillated.

-

Final version: Based on HA5KJ’s regulator design, effectively a hybrid series regulator with shunt-like feedback behavior. By lowering the MOSFET gate resistor from 100 kΩ to 22 kΩ, stability improved and the supply ran quietly, though with a narrower adjustment range.

PCB layout turned out to matter just as much as the schematic. My first board oscillated and destroyed MOSFETs; the second board, closely following my home etched, experimental, single-sided layout, has been reliable.

Update September 2025.

Since I wrote this, I have tested the linear. During initial adjustments, the screen regulator exploded. Literally. R2 evaporized, together with the metering shunt and all the mosfets. It started with a small hiss, and before I got time to react, it took off. Due to the current meter shunt being taken out, it also took out the Arduino Mega by piercing the analog input with high voltage. I had to do some research and failure analysis, and I've come to the conclusion that C2, which spans the feedback divider network might be wrong. I had by accident installed a 1 nF capacitor instead of 100 nF. I had also installed 100 nF from potentiometer wiper to ground and this, combined with a no load situation might be the cause of oscillations. From my understanding, you should install one of these capacitors, not both, because you may disrupt the phase margin. Each part of the regulator introduces response lag due to capacitances. Q3 has gate capacitance which takes some time to charge. Q1 and Q2 has gate capacitance which also takes time to drain or charge depending on which way we need to regulate. Series resistors cause lag. If the output of the regulator is delayed enough, we might end up with positive feedback depending on how we set up the feedback circuit. Also, the load we are feeding also impacts the response. The failure occurred with the amplifier idling. No current was drawn by the plates, and we had cut-off bias on the control grids. It could have been that the regulator bottomed out due to low load. It tried to maintain 800 V with no current being drawn, and ended up "hitting bottom" and began to oscillate due to incorrect feedback circuit.

This is (for me atleast) a complex area and I'm not quite sure how to tackle this. A defined load (bleeder) is a must. I will add a 30 K resistor stack to always have the regulator see a load, and shunt some of the non-linear load the screen represents. Regarding feedback capacitors I do not know. I have 3 choices. 1. Connecting a large-ish ,up to say 1 uF, capacitor across the potentiometer wiper and ground, which should filter out any quick changes and high frequencies. 2. HA5KJ placed 100 nF across Vout of the regulator and wiper so that's an option. 3. Omit them all. A lot of low voltage series regulators does not have any capacitors across the feedback voltage divider. This does however lets Q3, the error amplifier, to be open for everything that comes back down the feedback path.

What feels most "right" is to add a capacitor of say 100-500 nF across the wiper and ground. This should represent a very low impedance for frequencies above 90 Hz. Besides, it would only call for low voltage capacitor since the most voltage it´s going to see is around 27 Volts, ie, the zener reference voltage.

If all else fails. I´ll resort to eight OB2 gas regualtor tubes and a series mosfet. Just for kicks!

To be continued.

|

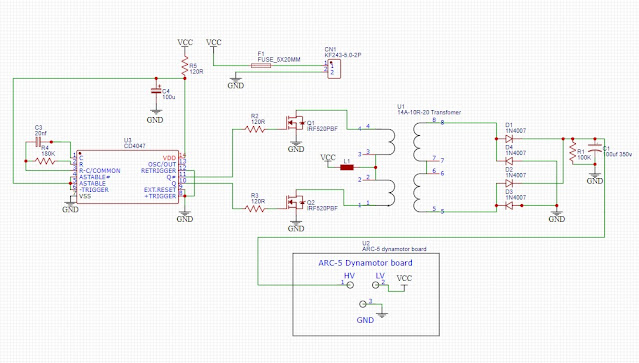

| HA5KJ series regulator for 2xGU81M |

|

| My version based on HA5KJ. Note R1 is decreased to 22K to get smoother regulation. Also, i added one more zener series resistor because I´m using higher voltages than HA5KJ |

|

| A simple series regulator. It failed due to temperature drift. A different approach could be to use VR tubes, say 8 OB2 in series for 864 V regulated. I got a call from a fellow SM amateur, who did just that, and claimed they dont drift the same as zeners do. Might be worth a try. |

Bias Supply

The bias supply is much simpler: a relay-switched zener shunt regulator.

The control grid draws negligible current, but the supply must still be able to sink current in case of RF overdrive. In my design:

-

Standby bias is about –320 V

-

Operating bias is stabilized at –220 V

Low-Voltage Supplies

The remaining supplies are conventional:

-

Unregulated 24 V for stepper motors and vacuum relays

-

Regulated 12 V for logic and control circuits

A 300 VA toroidal transformer with added turns provides the necessary voltages.

Comments

Post a Comment